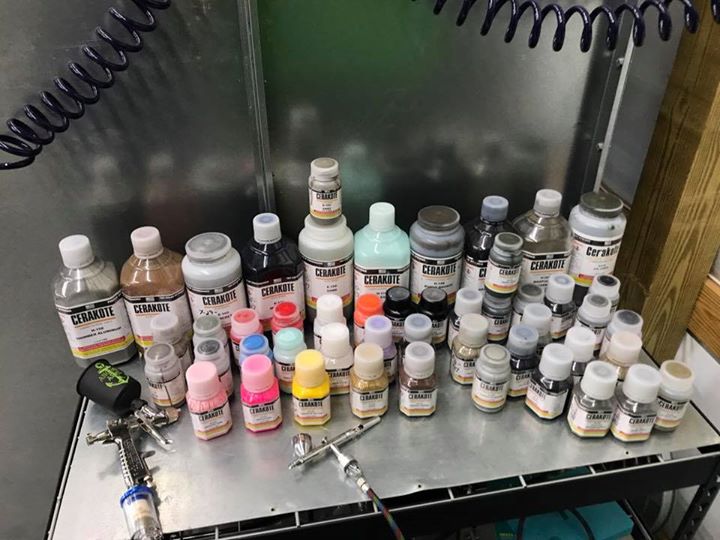

Cerakote Firearm Applications

What is Cerakote? Cerakote is a Polymer-Ceramic Composite coating that can be applied to metals, plastics, polymers and wood. The unique formulation used for Cerakote ceramic coating enhances a number of physical performance properties including abrasion/wear resistance, corrosion resistance, chemical resistance, impact strength, and hardness. Each of these properties is rigorously tested to guarantee that Cerakote products remain at the forefront of the ceramic coatings market. Cerakote ceramic coatings utilize state-of-the-art technology to out-perform any competitive coating in both laboratory settings and real world applications.

Custom Firearm Builds

Custom Stencils

What is Stencilling? - Stencilling produces an image or pattern by applying cerakote or other median to a surface over an intermediate object with designed gaps in it which create the pattern or image by only allowing the cerakote or other median to reach some parts of the surface.

Firearm & Accessory Sales

Firearms Manufacturing

Gunsmith Services

Manufacture of Full-auto weapons and suppressors

Stippling

What is Stippling? - Stippling is the creation of a pattern simulating varying degrees of solidity or shading by using small dots.

Ultra-Sonic Cleaning

What is Ultrasonic Cleaning - A process that uses ultrasound and an appropriate cleaning solvent to clean items. The ultrasound can be used with just water, but use of a solvent appropriate for the item to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned.

Ultrasonic cleaning uses cavitation bubbles induced by high frequency pressure (sound) waves to agitate a liquid. The agitation produces high forces on contaminants adhering to substrates like metals, plastics, glass, rubber, and ceramics. This action also penetrates blind holes, cracks, and recesses. The intention is to thoroughly remove all traces of contamination tightly adhering or embedded onto solid surfaces. Water or solvents can be used, depending on the type of contamination and the work piece.